Search

- Page Path

- HOME > Search

Original Articles

- Biomechanical finite element analysis of a femoral neck system fixation construct for femur neck fractures and clinical implications

- Hoon-Sang Sohn, Se-Lin Jeong, Gu-Hee Jung

- J Musculoskelet Trauma 2025;38(3):133-142. Published online July 22, 2025

- DOI: https://doi.org/10.12671/jmt.2025.00108

-

Abstract

Abstract

PDF

PDF - Background

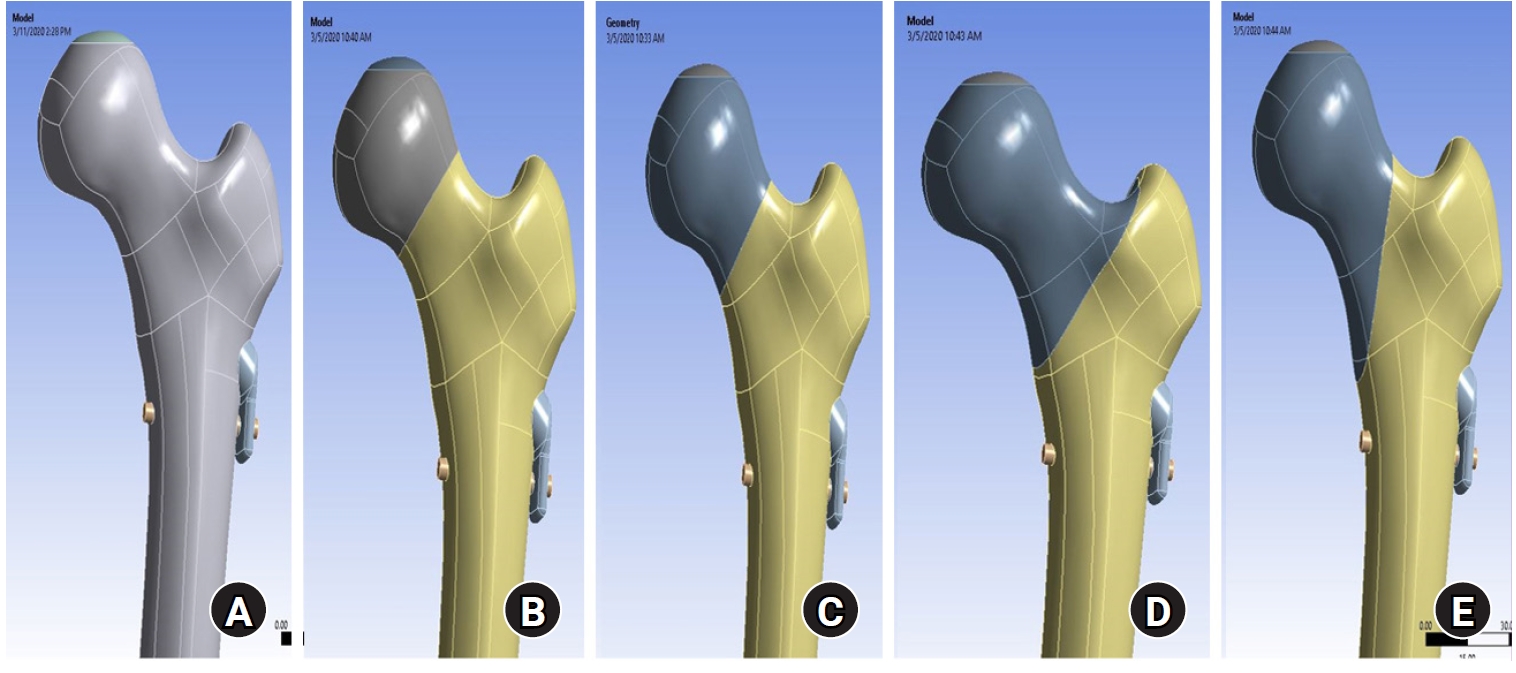

This study assessed the structural/mechanical stability of fixation constructs with a femoral neck system (FNS) via finite element analysis after simulating femoral neck fractures and explored the clinical implications.

Methods

We simulated subcapital, transcervical, basicervical, and vertical fracture models using a right femur (SAWBONES) and imported the implant model of FNS to Ansys (Ansys 19.0, Ansys Inc.) to place the implant in the optimal position. The distal end of the femur model was completely fixed and was abducted 7°. The force vector was set laterally at an angle of 3° and posteriorly at an angle of 15° in the vertical ground. The analysis was conducted using Ansys software with the von Mises stress (VMS) in megapascals (MPa).

Results

The maximum VMS of the fracture site was 67.01 MPa for a subcapital, 68.56 MPa for a transcervical, 344.54 MPa for a basicervical, and 130.59 MPa for a vertical model. The maximum VMS of FNS was 840.34 MPa for a subcapital, 637.37 MPa for a transcervical, 464.07 MPa for a basicervical, and 421.01 MPa for a vertical model. The stress distribution of basicervical and vertical fractures differed significantly, and the basicervical fracture had higher VMS at the bone, implant, and fracture sites.

Conclusions

FNS fixation should be performed with consideration the osseous anchorage in the femoral head, and this technique might be appropriate for vertical fractures. Regarding the VMS at the fracture site, FNS might be applied cautiously only to basicervical fractures with anatomical reduction without a gap or comminution. Level of evidence: IV.

- 1,819 View

- 82 Download

- Biomechanical Investigation to Establish Stable Fixation Strategies for Distal Tibial Fractures in Various Situations: Finite Element Analysis Studies

- Sung Hun Yang, Jun Young Lee, Gu-Hee Jung, Hyoung Tae Kim, Ba Woo Ko

- J Korean Fract Soc 2024;37(2):71-81. Published online April 30, 2024

- DOI: https://doi.org/10.12671/jkfs.2024.37.2.71

-

Abstract

Abstract

PDF

PDF - Purpose

This study examined the structural and mechanical stability as well as the clinical significance of various fixation constructs for distal tibial fractures using finite element analysis.

Materials and Methods

Fracture models with 20 mm and 120 mm defects were produced, and implants of an intramedullary nail and anatomical plate model were applied. An axial load of 800 N with 60% distribution in the medial compartment and 40% in the lateral compartment was applied and analyzed using Ansys ® software.

Results

In the intramedullary nail model, the maximum von Mises stress occurred at the primary lag screw hole and adjacent medial cortex, while in the plate model, it occurred at the locking holes around the fracture. The maximum shear stress on the bone and metal implant in the fracture model with a 20 mm defect was highest in the plate assembly model, and in the fracture model with a 120 mm defect, it was highest in the two-lag screw assembly model.

Conclusion

Based on an analysis of the maximum shear stress distribution, securing the fixation strength of the primary lag screw hole is crucial, and the assembly model of the intramedullary nail with two lag screws and a blocking screw applied was the model that best withstood the optimal load. Securing the locking hole directly above the fracture is believed to provide the maximum fixation strength because the maximum pressure in the plate model is concentrated in the proximal locking hole and the surrounding cortex. -

Citations

Citations to this article as recorded by- How to obtain the desired results from distal tibial nailing based on anatomy, biomechanics, and reduction techniques

Jungtae Ahn, Se-Lin Jeong, Gu-Hee Jung

Journal of Musculoskeletal Trauma.2025; 38(2): 74. CrossRef

- How to obtain the desired results from distal tibial nailing based on anatomy, biomechanics, and reduction techniques

- 904 View

- 19 Download

- 1 Crossref

E-submission

E-submission KOTA

KOTA TOTA

TOTA TOTS

TOTS

First

First Prev

Prev